Please, in order to enter to the members area fill in the boxes below this lines.

Please type your email address below and you will shortly receive an email.

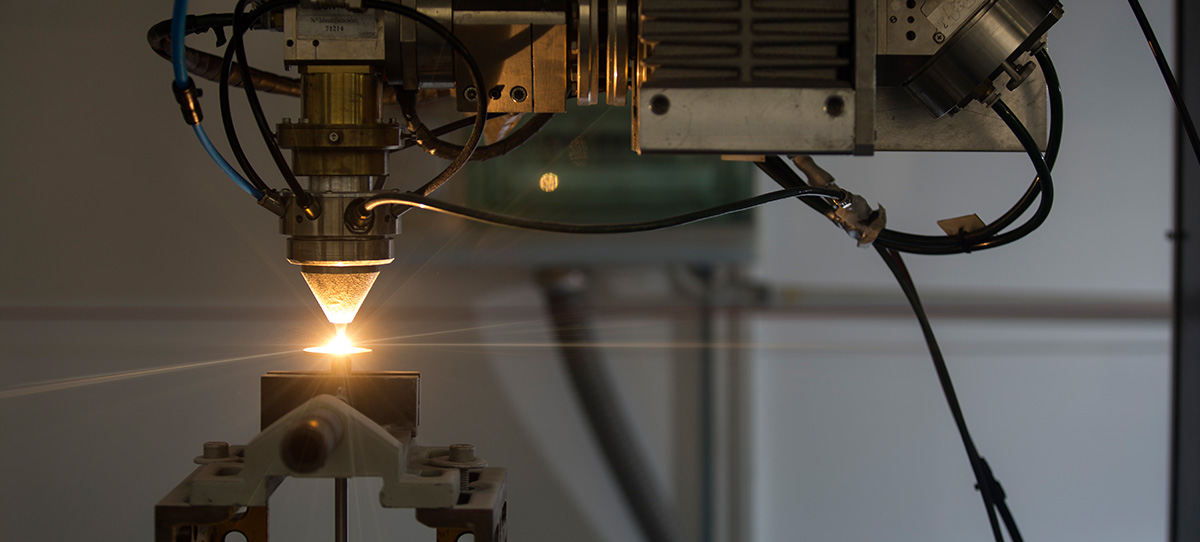

Advanced laser surface hardening of microalloyed steels for fatigue enhancement of automotive engine components

Fatigue strength of crankshafts needs to be improved to meet today’s demands of higher performance automotive engines. In some cases, fatigue improvement can be difficult to reach due to poor residual stress distributions in relation to non-uniform/heterogeneous surface strengthened layers produced by standard techniques. In STIFFCRANK, experimental and simulation tests together with extensive X-ray measurements, detailed microstructural analysis and fatigue testing of laser surface hardened steels and crankshafts will allow defining new strategies of tailoring the energy distribution for optimization of residual stress field. This will lead to enhanced fatigue, enabled by using new advanced laser surface hardening methods.

The goal of STIFFCRANK is to develop a new laser-based surface hardening methodology for tailoring the distribution of residual stresses near the surface in relation to improved fatigue resistance, through the generation of homogeneous and predictable surface hardened layers in microalloyed and alloyed-steels, and minimizing and/or eliminating scattered data of fatigue strength, heterogeneous microstructures and non-uniform hardness profiles generated by conventional surface hardening techniques. The achievement of this target will require improved understanding of the link between the distribution of residual stresses in the surface hardened and subsurface layer and the resultant microstructure after laser surface hardening techniques, with respect to the resultant fatigue strength of specimens and crankshaft components, and the way these are affected by the laser hardening process. From the accomplished knowledge, innovative laser surface hardening techniques for surface strengthening of high-performance steel components and parts subjected to heavy loads and stresses will result, including the guidelines for advanced laser surface hardening of crankshafts and the correspondence benchmark testing with currently employed SoA techniques.